Introduction

Brief Introduction to BHMTPMPA

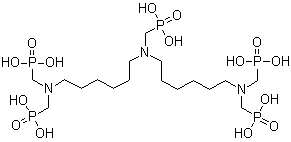

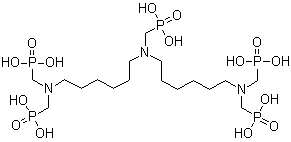

BHMTPMPA, with the CAS number 34690-00-1, is also known by several synonyms such as Bis(hexamethylenetriaminepenta(methylenephosphonic acid)). Chemically, its molecular formula is C17H44N3O15P5, and it has a molar mass of 685.41. It typically appears as a dark amber liquid.

As a scale inhibitor, BHMTPMPA plays a crucial role in both general water treatment and various industrial applications. In water treatment processes, it is designed to combat the formation of scale deposits. Scale is mainly caused by the precipitation of insoluble salts like calcium and magnesium compounds in water. BHMTPMPA has excellent chelating properties, which means it can bind with metal ions such as calcium ions effectively. For instance, in industrial cooling water systems, where water is constantly recycled, the concentration of dissolved salts gradually increases over time due to evaporation and other processes. Without proper scale inhibition, these salts would deposit on the inner walls of pipes, heat exchangers, and other equipment, reducing heat transfer efficiency and potentially causing blockages.

Importance of Understanding Its Usage and Certifications

For relevant industries and professionals, having a comprehensive understanding of which industries commonly use BHMTPMPA and the necessary certifications is of utmost importance.

Firstly, different industries have diverse operating conditions and water quality requirements. For example, in the textile industry, water is used in various processes such as dyeing and washing. The water used here needs to be free from scale deposits to ensure the quality of the fabrics and the proper functioning of the equipment like dyeing vats and washing machines. Similarly, in the food and beverage industry, where hygiene and product quality are paramount, any scale formation in water pipes or processing equipment could potentially contaminate the products. By knowing that BHMTPMPA can be effectively used in these settings as a scale inhibitor, industry professionals can make informed decisions to maintain optimal production conditions and meet quality standards.

In the oil and gas industry, water is often present in extraction, refining, and transportation processes. Scale formation in pipelines and oil recovery equipment can significantly impact production efficiency and increase maintenance costs. Understanding that BHMTPMPA can help prevent such issues allows operators to implement appropriate preventive measures.

Secondly, regarding certifications, they are essential to ensure the proper and legal application of BHMTPMPA. Certifications act as a guarantee of the product's quality, safety, and compliance with relevant regulations. For instance, in many countries, chemical products like scale inhibitors need to meet certain environmental protection standards. Certifications verify that BHMTPMPA has been tested and proven to have minimal impact on the environment during its usage and disposal.

Industries Commonly Utilizing BHMTPMPA as a Scale Inhibitor

Water Treatment Industry

In municipal water treatment plants, BHMTPMPA plays a vital role in maintaining the smooth operation of the entire water supply system. Municipal water comes from various sources such as surface water like rivers, lakes, and reservoirs or groundwater. These water sources often contain different levels of hardness-causing ions like calcium and magnesium. When water is treated and distributed through a complex network of pipes and stored in reservoirs or water towers before reaching consumers, the potential for scale formation is significant.

BHMTPMPA is added during the treatment process to prevent scale build-up. For example, in the initial filtration and sedimentation stages, where large particles are removed, BHMTPMPA can be dosed into the water to start chelating with the metal ions present. As the water then moves through the distribution pipes, its continued presence inhibits the precipitation of these ions as scale on the inner walls of the pipes. This ensures that the diameter of the pipes remains unchanged, allowing for consistent water flow rates. In storage tanks, it prevents scale from accumulating on the surfaces, which could otherwise lead to contamination of the water and affect its quality when it's finally supplied to households and businesses.

Industrial Manufacturing

n chemical plants, numerous chemical reactions take place in reactors under specific temperature, pressure, and pH conditions. Many of these reactions involve the use of water or water-based solutions, and the presence of metal ions in the water can lead to scale formation. For instance, in processes where alkaline chemicals are produced or used, the high pH environment can cause precipitation of calcium and magnesium compounds if not properly controlled.

BHMTPMPA is employed in chemical plants to safeguard the reactors. It is added to the process water or reaction mixtures to chelate with metal ions, preventing them from coming out of solution and depositing as scale on the inner walls of the reactors. This is crucial because scale build-up can reduce the heat transfer efficiency in exothermic or endothermic reactions, disrupt the mixing of reactants, and even lead to hot spots or uneven reaction rates. In addition, in the cooling systems of chemical plants that are essential for maintaining the proper operating temperature of reactors and other equipment, BHMTPMPA plays a similar role. As cooling water circulates through heat exchangers and cooling towers, it has a tendency to accumulate scale over time due to evaporation and concentration of dissolved salts. By using BHMTPMPA, the cooling systems can operate continuously without the need for frequent shutdowns for descaling or equipment repair, ensuring uninterrupted production and avoiding costly damage to expensive reactors and associated components.

Power Generation

In thermal power plants, both cooling towers and boilers are critical components where scale prevention is essential. In cooling towers, water is continuously recycled to remove heat from the power generation process. As the water evaporates during this process, the concentration of dissolved salts, including those that can form scale like calcium carbonate and calcium sulfate, increases. If left unchecked, scale would accumulate on the heat exchange surfaces of the cooling tower fill and heat exchangers.

BHMTPMPA is added to the cooling tower water to inhibit scale formation. By chelating with the metal ions responsible for scale formation, it keeps the water in a soluble state and prevents the precipitation of these salts on the surfaces. This ensures efficient heat transfer between the hot water from the power generation process and the ambient air, reducing the energy consumption required to cool the water. In boilers, which are used to generate steam for driving turbines, scale formation on the inner walls can have a significant impact on energy efficiency. A layer of scale acts as an insulator, reducing the heat transfer from the combustion gases to the water, resulting in the need for more fuel to generate the same amount of steam. BHMTPMPA is dosed into the boiler feedwater to prevent scale from depositing on the boiler tubes. This maintains the proper heat transfer, improves the overall energy efficiency of the boiler, and prolongs the lifespan of the boiler tubes by reducing the risk of overheating and corrosion caused by scale-induced hot spots.

Oil and Gas Sector

In oilfields, water injection is a common technique used for enhanced oil recovery. Water is injected into the oil reservoirs to maintain pressure and push the oil towards the production wells. However, the water used in these injection systems often contains various dissolved salts and metal ions. As the water moves through the injection wells and the reservoir rock formations, changes in temperature, pressure, and chemical composition can trigger scale formation.

BHMTPMPA is added to the injection water to prevent this scale build-up. In the injection wells, it stops scale from depositing on the inner walls of the well casings and the tubing, ensuring that the flow of water into the reservoir remains unobstructed. This is crucial for maintaining the proper pressure distribution within the reservoir and maximizing the efficiency of oil displacement. In the pipelines that transport the produced oil and water mixture from the wells to the surface processing facilities, BHMTPMPA continues to play a role in preventing scale formation. Scale in these pipelines could reduce the flow capacity, increase the pressure drop, and even lead to blockages over time. By inhibiting scale, BHMTPMPA helps to ensure a smooth and continuous flow of the oil and gas mixture, facilitating efficient extraction and transportation processes.

Conclusion

Summary of Key Points

In conclusion, BHMTPMPA is a versatile and effective scale inhibitor that finds application in a wide range of industries. In the water treatment industry, it is crucial for both municipal water treatment plants and in dealing with different water sources like surface water and groundwater. It helps prevent scaling in pipes and equipment, ensuring efficient water distribution and high-quality water supply. In industrial manufacturing, it safeguards reactors and cooling systems in chemical plants and maintains the hygiene and proper functioning of processing equipment in the food and beverage industry.

In power generation, it plays a significant role in cooling towers and boilers of thermal power plants and also has importance in hydropower plants related water systems. In the oil and gas sector, it is used in oilfield water injection systems and refineries to ensure smooth extraction, transportation, and processing of oil and gas.

The working mechanisms of BHMTPMPA involve chelation, dispersion, and lattice distortion effects. Through chelation, it binds with metal ions like calcium and magnesium to prevent their precipitation. Its dispersion effect keeps potential scale particles suspended in water, and the lattice distortion effect disrupts the growth of scale crystals.

Future Outlook

Looking ahead, the usage of BHMTPMPA is likely to witness several trends. As environmental regulations become more stringent globally, there will be an increased focus on developing even more environmentally friendly formulations of BHMTPMPA with enhanced biodegradability and lower ecological impacts. This could lead to further research and innovation in its chemical structure modification to meet these evolving requirements.

In terms of certifications, with the continuous improvement in testing methods and a better understanding of the long-term effects of chemicals in different applications, we can expect new and updated certifications to emerge. For example, more specific certifications related to its performance in advanced water treatment technologies or in emerging industries that rely on water systems could be developed.